Hot Dip Galvanizing

Hot Dip Galvanizing

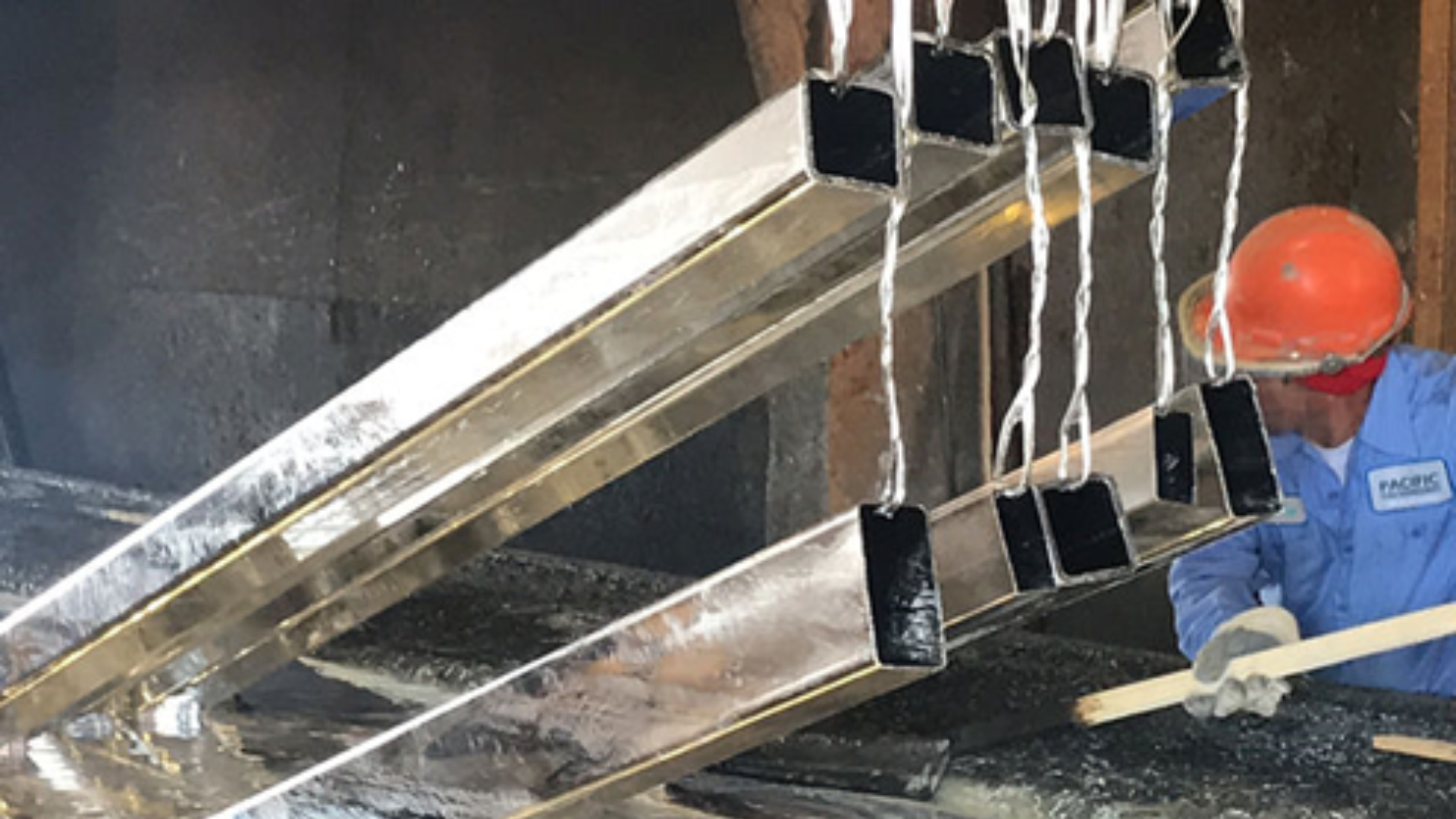

Bakriya Industries offers hot-dip galvanizing (HDG) in one of the largest galvanizing kettles in the locality. Hot-dip galvanizing (HDG) is the process of coating fabricated steel by immersing it in a bath of molten zinc.

There are three fundamental steps in the hot-dip galvanizing process: surface preparation, galvanizing, and inspection.

Hot-dip galvanizing provides several benefits to the steel it protects. The metallurgically bonded zinc-iron alloy layers not only create a barrier between the steel and the environment but also cathodically protect the steel.

The cathodic protection offered by zinc means the galvanized coating sacrifices itself to protect the underlying base steel from corrosion.

The tightly adhered coating, which has a bond strength of around 3,600 psi, is also extremely abrasion resistant as the intermetallic layers are harder than the base steel. However, even if the coating is damaged, zinc’s sacrificial action will protect exposed steel up to 1/4 inch away.

In addition to the cathodic protection offered by hot-dip galvanizing, there are a few other characteristics of the coating that provide longevity.

First, the reaction in the galvanizing kettle is a diffusion process, which means the coating grows perpendicular to the surface, ensuring all corners and edges have at least equal thickness on flat surfaces.

Furthermore, the complete immersion in the zinc bath provides total coverage of the steel, including the interior of hollow structures.

Benefit Highlights: Appearance, Safety, Speed of Construction, More with Less, Planning for the Future, Corrosion Protection.

Bakriya Industries supplies hot-dip galvanized products based on the industry’s requirements by following various industry standards, such as

ASTM A123/A123M Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products and ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles—Specifications and test methods and delivering them to the customer by meeting the project specification

Get In Touch

Bakriya Industries Co. Ltd. (BIC) - Galvanizing

Contact Point-1: Aladdin Mohammed (Plant Manager)

MOB. NO.: +966 56 833 3233

E-MAIL: ENG.ALAA@BAKRIYA.COM

CONTACT POINT-2: Nasser Atif (Sales Manager)

MOB. NO.: +966 56 692 9550

E-MAIL: NAATIF@BAKRIYA.COM

COMPANY RE-ESTABLISHED DATE: 2022

LEGAL STATUS: LIMITED LIABILITY

NATIONALITY: 100% SAUDI COMPANY